Our boat is blocked up and tightly wrapped inside her white plastic cocoon, waiting for spring to hit the water again. But just because she is winterized does not mean that work does not continue over the winter. There is plenty that needs to be done.

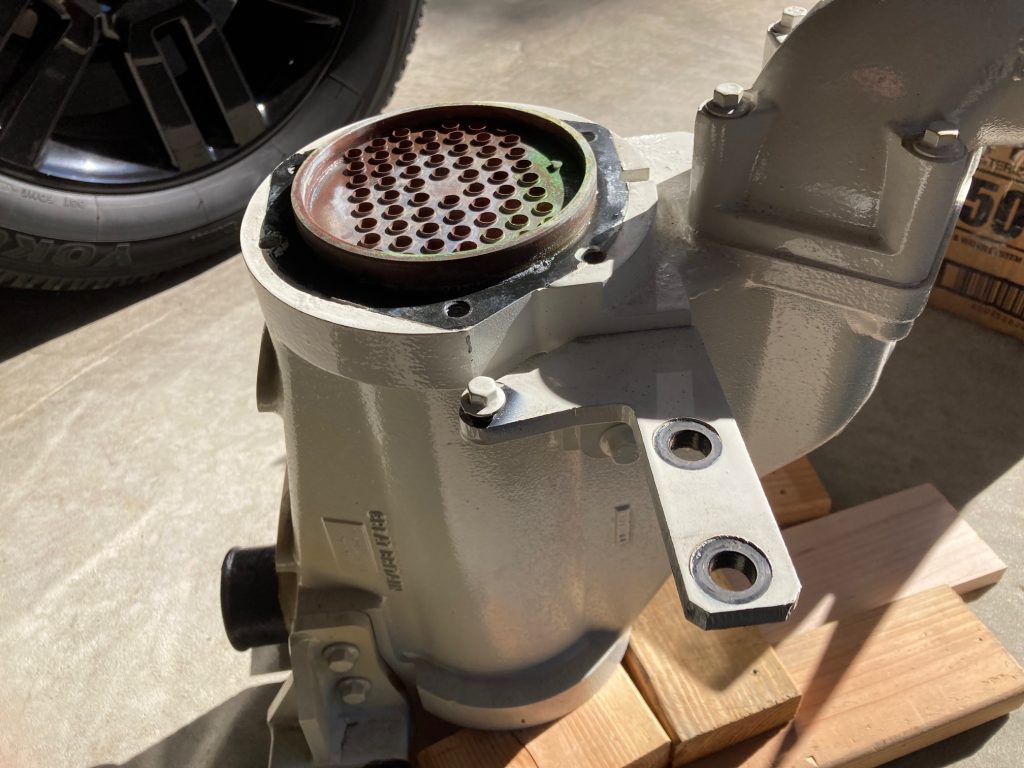

After the oil changes, winterizing and getting her hauled out for storage I went ahead with some work to get done at home during the off-season. Number one on my list was servicing the aftercoolers. If you don’t know what an aftercooler is, think of it as a radiator like in your car. It cools air by flowing water through copper tubes, and hot air flows around from the turbocharger, which feeds to the engine. It is just the opposite of your car radiator that cools the engine water by flowing air through the radiator.

Some engines use the same coolant the engine uses to cool down that air from the turbocharger, but I would say most marine engines use seawater to cool that hot air. And if your boat is in salt water, you have some routine maintenance you should perform every few years. Aftercoolers are usually made from aluminum, copper and brass and bronze. Those dissimilar metals immersed in saltwater tend to be prone to corrosion. To prevent that it is recommended that they be serviced every three years. That service interval can be extended if they are freshwater flushed after every use. We moved our boat down from the Great Lakes in August of 2023 and I quickly fabricated a flush system just for the engines and generator.

I worried that the boat was eighteen years old and even though it was in freshwater I wanted to perform the service and know what condition the aftercoolers were in, given that they are roughly five thousand dollars, each. And if they start leaking salt water into the engine you would have some very expensive repairs. So, before the boat was wrapped and after I was done getting her winterized, I went ahead and removed the coolers. By the condition of the paint, I could tell they were never removed.

I removed the starboard aftercooler first since it was the easiest to get to. Once I had that off and knew the best way to remove them I took off the port side aftercooler.

Working upside down leaning over the port engine took a bit more time but they both came off fairly easily. I have to say lifting the port side aftercooler over the engine from a cramped position took some effort! They are a little bigger than the ones on our last boat.

I took them home and the first thing I did was to place them in a bucket filled with a salt dissolving solution for an hour or so. After that, I removed both end caps and sprayed some penetrating oil around the area between the housing and core. Placing the housing and some wood for clearance, I used a small wood block and a mallet to knock the core or bundle out of the housing. With some persuasion, the bundles slid out from both housings. They looked to be in nearly new condition, something I attribute to being in fresh water and then flushing the engines when we got her home. One thing I did note was the complete lack of any grease around the seals and that the stainless-steel bolts used in the end caps were installed completely dry. I was lucky they came out with considerable effort but without any galling of the threads. I will use some never-size compound on them and a liberal amount of grease on the seals when it all goes back together. I am now waiting for the o-rings to assemble the aftercoolers for installation.

Next on the list is the air intake system of the engines. These engines are equipped with AirSep induction systems that include air filters, mist coalescers for crankcase blow-by and other parts. Just before Thanksgiving I put them in my cart direct from the manufacturer but wanted to wait a few weeks before I purchased them. When I went back to order them the price had jumped over one hundred and thirty dollars! I called them up the next day and after talking to an agent they honored the original price, making me very happy. I asked why the big jump, and he told me suppliers were raising prices on the raw materials across the board. So, if you need parts you may want to look into getting them sooner than you normally would for the spring launch.

Before installing the aftercoolers, I have to replace the oil pressure sensor located behind a plate that the engine electronics are mounted to. Of course, it is on the outside of the port engine so I will be working upside down once again. When that’s done, I can put it all back together.

In the meantime, after I get all the leaves collected and removed from the lawn and the equipment serviced, I have a new oak floating floor in my upstairs hallway to install. Actually, I started it but had to backtrack on it some. Seems the subfloor is not level enough for a floating floor and I have to remove the subfloor and level the floor joists.

And I thought I had an easy winter planned!