I have done most of the work associated with home ownership by myself. I am talking about painting, new flooring etc. During the twenty-three years or so of owning a boat I have done the majority of maintenance myself. Having mostly diesel-powered boats I have done routine maintenance as well as injector replacement, water pumps, new electronics and even air conditioning work. Inevitably my lovely wife will ask me (after the twenty-minute job lasted a few hours) “how did you learn all this stuff”?

The answer is really a combination of training, experience, observation and trial and error. Believe me, many mistakes were made along the way. Youthful enthusiasm comes into play early on. Years later a co-worker said it perfectly, “often wrong but never in doubt”. Sometimes I wonder how I am still alive with some of the things I did as a kid. My brother had some small lights pre wired, and I wanted to see how bright they were. I guess they were for a model and powered by a battery. So, I stuck the two wires into an electric socket and the light exploded in my face. Once at a friend’s house we wanted to make a jet engine, so we sucked some gasoline into a canister vacuum while it was running and nearly set fire to his garage.

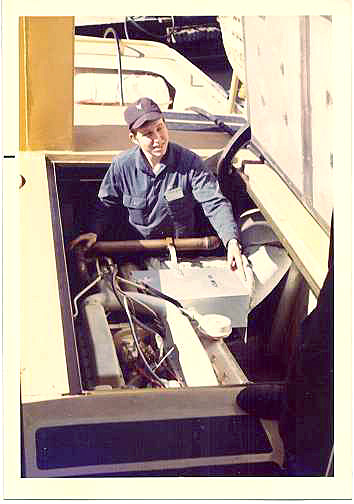

My dad taught me all about tools. When he wanted a tool, he would tell me to go get it and it took some time to know what he wanted. Even longer to know where they were. If he said go get me a Phillips head screwdriver I would ask where it was. He would answer “if I knew where it was, I would get it myself”!Formal training began after high school when I enlisted in the United States Coast Guard. After boot camp in Cape May New Jersey, I went to Engineman School in Yorktown Virginia. After you graduate from that school you receive an “MK” rating but you are called a Machinery Technician. “MT” was already taken by another rate, and “MKs” are sometimes called “machinery killers”! The school was about fourteen weeks and I will just say it was a crash course in what you need to know to function as an engineer on one of the boats or ships you could be assigned to. Engines, welding, refrigeration, plumbing and more were taught there. I think two weeks were devoted to tearing down an engine by a team of four students per engine. Some worked on Detroit Diesels, I worked on Cummins VT-903 engines that were installed in the new forty-one-foot boats.

After graduating I was stationed at Governors Island in New York Harbor. We would strip boats bare and rebuild them and the Detroit diesel 6-71s. You learned quite a lot about how they were made just by repetition. About a year after getting there the station got a new forty-one-foot boat powered by the Cummins VT-903 engines. I was the only one that had gone to Cummins school so I was put on that boat as the engineer. Since it was a newer boat, I did not have to perform much work on her and helped the other engineers on their steel boat from the 1950s. The worst I had to do on the forty-one was after the big oil spill on the Gowanus Canal. The engines had idled for days in freezing temperatures and eventually the injectors fouled and we pulled an all-nighter replacing them in both engines. In time I was transferred to Station Eaton’s Neck, one of the busiest stations on the east coast at the time. I was put to work right away there as one of the crews had what they believed was a “run-away engine”. That can happen if the diesel somehow gets its own engine oil in large amounts into the combustion chamber. So, they emptied a dry chemical fire extinguisher into the air intake of the 6-71 and then realized the metal tachometer cable had fallen across the starter terminals. I spent a good deal of time cleaning out the air intakes and ports in the block!

What got me thinking about all this was my wife asking the same question again while out in my shop. I was unboxing a propeller puller I recently obtained after searching for this brand for a few years. I started laughing and remembered a story from Eaton’s Neck. We had to take a forty-one over to Base New Haven to haul out and replace the props among other things. My chief told me they would have the tools I needed to get those props off and indeed they did. The Engineering Chief gave me a hydraulic porta-power with the attachments I would need to pull the props. It was a cold miserable night while doing this, and in time I had the shaft nuts off and the hydraulic puller all set to go. I started pumping the handle on the puller and it took some time to work, but when it did that prop shot off and landed about ten feet behind the boat. Talk about power, wow. Unfortunately for me it cut the hydraulic line when it landed and I had to go back to the chief and explain what happened. After a few choice words he gave me another line and left for home. Again, I got the other prop set up and started pumping the porta- power handle. And once again the prop shot off like a rocket and you guessed it, cut the second line. I got the new propellers installed and the boat was launched for us to head back to Eaton’s Neck. I returned the porta-power to another engineer at the base and after explaining what happened, went back to the boat and we headed home! After that, I knew to leave one shaft nut on to stop launching those propellers.

As the man says on tv, “we know a thing or two because we’ve seen a thing or two”!