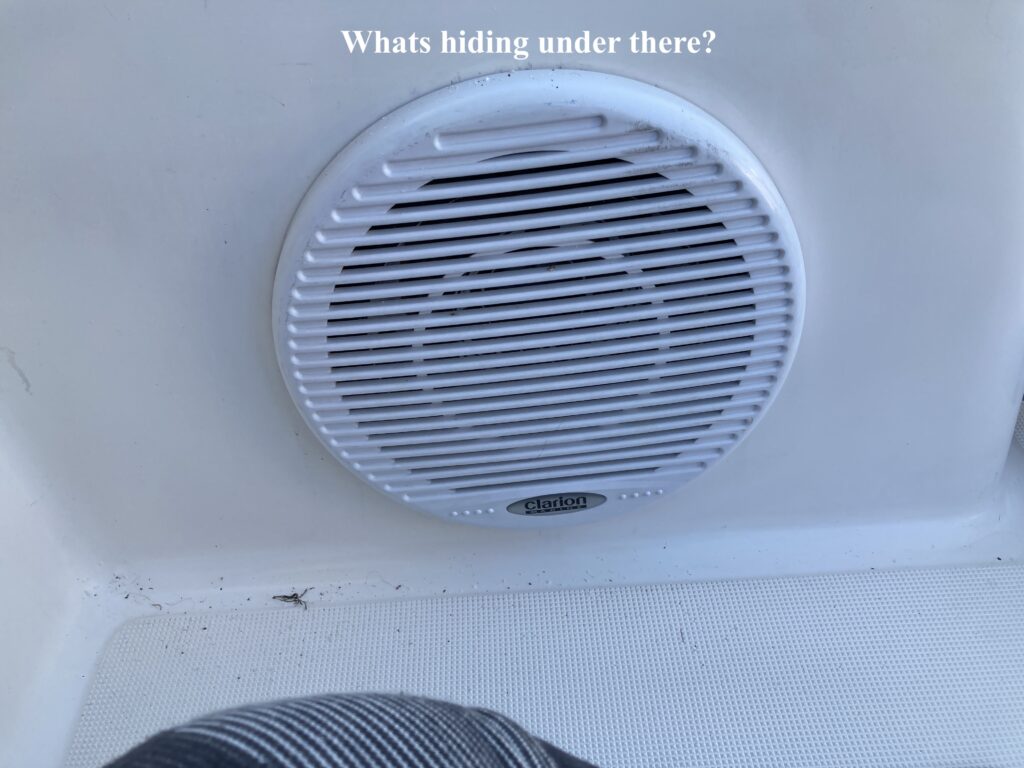

Have you ever heard the expression, “If you didn’t have bad luck, you’d have no luck at all”? That’s how I have been feeling the past few weeks as some equipment on the boat failed or needed replacement. Last month one of the things I wrote about was replacing the stereo and what I had to do to find a replacement that fit. After I powered it up, I noticed one of the three cockpit speakers sounded odd, like there was something loose in it. Back in the day if a speaker in our car started making a funny noise you could fix the rip in the speaker cone with some nail polish or glue. I figured maybe that was the case here.

After a couple of visits to see our five-month-old grandson, I got around to taking the grill off of the suspected speaker. When I got the grill off all I could do was laugh. I guess nineteen years takes its toll. Maybe my speakers had speaker termites? Might as well check the other speaker and the subwoofer too. You guessed it, destroyed. It was hard to believe I was getting any music out of these speakers. My First Mate asked me what I was laughing at and when I showed her the speakers she just said, “Wow”!

So, I had to replace the three speakers, seemingly an easy task. I went home and started searching for “marine speakers”. Have you looked at speakers lately? This six and a half inch speaker needs a five inch cutout while this one needs a five and one eighth inch cutout. I was really trying to avoid having to make the holes larger and getting a new speaker to fit. Since the old speakers were still in the boat and I had no idea what size cutouts they required or even what power characteristics they had, I sent an e-mail to the boat manufacturer. They have been very helpful in the past and responded quickly. he sent the make and model of the speakers and I was able to compare new ones. I ordered new speakers and had them in a few days.

We went out in the evening to install them, during the late July heat wave. Luckily, we had the air conditioning running and we could retreat to the cabin to cool off frequently. It actually went very smoothly, maybe it took an hour altogether. They all fit in the cutouts with no enlargement needed. I did have to drill new holes for the mounting screws but that was it. After a quick cleanup I turned on the stereo and sat there enveloped in sound. What a difference.

After putting the tools away, we went down into the cabin to cool off and get a cold drink. Something was not quite right. It was warmer than it should have been. I looked over at the air conditioner control and saw it was not cooling, it had an error code “HPF”. High Pressure Fault, usually meaning the refrigerant is not getting cooled. A look over the side showed no water coming out of the cooling water outlet. Just what we needed. After the two of us lifted the six-foot fish box out of the rear deck I could hear the cooling water pump humming but not working. I climbed down and felt it, hot. This happened a couple of years ago also, and I had a trick that got it running. At that time, I plumbed in a fresh water flush out. So, I hooked up a hose from the dock and turned the hose on. The pump started humming again, so I hit it with my fist! And, it started running again! The cabin cooled down and after letting it cycle through a couple of times we left for the night.

It was a few days before we could get back to check on the boat and I was not comfortable wondering if the system was working or if the pump had failed again. We did get out on another beastly hot and humid day to find that the pump had failed, time for a new pump.

Again, it was time to search for the replacement and it should be here in a few days. Looking at the system to make a plan of attack, it’s not going to be easy. One it’s down in the aft bilge. Two, when they installed this at the factory, they must have installed the pump and sea strainer as a one-piece unit. They are connected by a short pipe nipple. I really do not want to take the entire assembly apart as one and then put it all back in one piece. It will be bulky and heavy. My current plan is to get the pump off by either sawing that nipple of by taking the pump face off (if I can get to the screws) and then just spinning the face off. From there I think I will put a hose barb into the sea strainer and another into the pump, and use a length of hose to mount the pump away from the strainer. It should be a real help down the road.

Now, speaking of luck, as a boat owner yesterday may have been the luckiest day for a bunch of us at the marina. Just around quitting time with only a handful of employees still there, smoke started billowing out of one of the larger boats on our dock. Hats off to them as they were able to call the fire department and move the two boats directly next to the burning boat. They moved them apparently saving them from any damage at all. If you have ever seen a boat go up in flames, you know how quickly it can spread. Great job guys!