I have stepped on, walked on, sat on, tied off, fished off and fallen off more docks than you can imagine. So I consider myself an expert on docks, be they set piers or floating. In the cause of honesty, I will admit that every time I fell off one, the fault was clearly mine. I’ll just leave the confession at that, but I do nail my wasted cell phones to one of the pilings. There are seven there now.

Over so many years of securing my vessels to docks, you can’t help noticing that dock maintenance is often an “I’ll get to that later” affair.

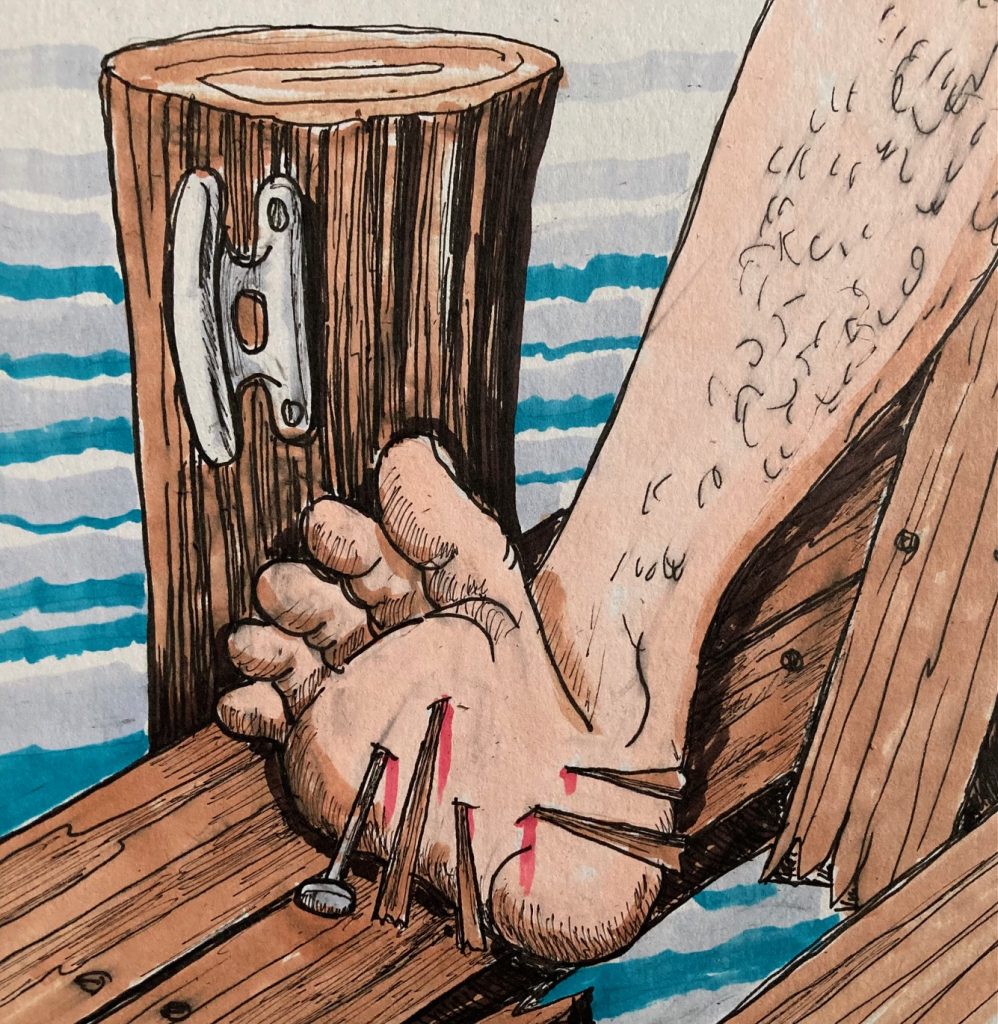

Later soon becomes never, until chains rust through and the floater does what it does best-floats away! Then there’s the loose cleat scenario. I’m sure you’ve run into that when visiting another boater’s house. You go to tie your lines and only one side of the cleat is still attached so they kinda “Swivel”. That’s not going to make you feel your vessel is secure. Then you step off your gunnel onto a loose dock deck board that clearly has a split in the middle. It’s a crying shame that you were playing it “Salty” and were barefoot because that pressure-treated splinter you just got, and will ignore till tomorrow, is hard to get out and gets infected fast.

It amazes me when I see a floating dock that is sinking because it lost some of its floatation during Sandy, was never repaired, and now has half of its surface underwater yet has a brand new $300,000 fishing machine tied to it. I’d say this Captain has his priorities a tad askew. It doesn’t take that much to repair that situation early on. New floatation could have been added without lifting the docking out of the water in some situations. (I said “some” meaning almost never!) But the fact is, if you can afford that boat, you can almost certainly afford to have your dock fixed or replaced by a professional. Living on the water and having a bay house, I’ve had to deal with every situation over the years concerning dock repairs including jetting in pilings, etc., so I find that letting your dock degrade seems foolish and dangerous.

Much of the hardware used on docks no longer has the quality of thirty years ago. This means you must be on it all the time. Galvanized deck nails are imported and rarely “Hot Dipped”. You can go online to find the best nails and screws (consider stainless). But whatever you use, replace any deck fasteners that show signs of degradation. Do not use nail gun fasteners as the head are too small and they don’t hold up, Sure, it’s harder to hand nail or screw down but it’s worth the time.

Your method of attachment to the pilings, whether rings or chains, needs attention – keep at it. A small amount of rust becomes a “rust through” very fast in salt water. Check out the condition of your pilings. They tend to rot out at the sand line. Replace them when they get too thin.

Keep after the surface of your dock’s deck. It’s important to wash your deck with a deck brush and remove all mold. It builds up fast and becomes slippery when wet. When you wash down your boat after a trip, take time to take on at least part of the deck after each trip. Handle it this way and it never gets away from you. If your docking facility is a pier type, check all the decking, pilings, etc.

Having boardwalks, a pier, and two floating docks to maintain, I have been experimenting with the longevity between pressure and non-pressure-treated lumber for decking when not in contact with the ground. The pressure-treated lumber of today does not hold up the way it did years ago. It’s your call what works best for you when it comes to decking. Some folks swear by Trex and other brands of recovered decking materials. It all comes down to this. Take care of your docks and your docks will take care of your boat and you.

See you on the water,

Captain Eddy